SBS Bitumen

Materials that last

SBS bituminous roll materials

Overview of SBS Bitumen Rolling Compounds

Modern bituminous roof coatings are high quality materials with solid technical characteristics, uniform structure and manufacturer’s guarantee. Quality SBS bituminous roofing has a lifespan of at least twenty years.

SBS (styrene butadiene styrene) bituminous materials contain elastomeric modifiers that ensure SBS materials have excellent low temperature elasticity, are coated with a slate layer for UV protection and are resistant to temperature fluctuations.

The materials are reinforced with polyester or fibreglass fabric and can be installed in single, double or triple layers according to the roof pitch.

The modifiers used in bitumen ensure the consistent technical performance of roofing materials and increase their resistance to environmental influences.

SBS products

| External fire safety | Broof (t1); Broof (t2) |

| Fire response | E |

| Waterproofing | 300 |

| Mass per unit area, kg/m2 | 5.0±0.25 |

| Thickness, mm | 4.0±0.2 |

UNIFLEKS EKP 5,0

To be used as a top coat, suitable for new roofs as well as for renovation work.

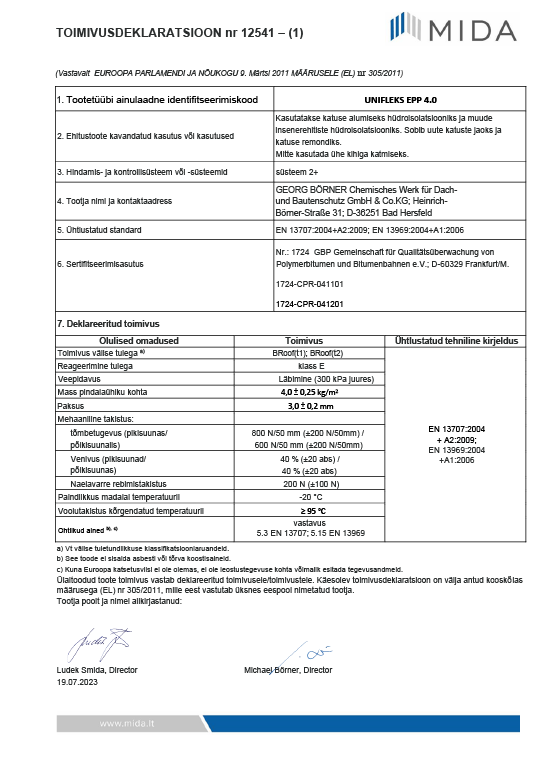

UNIFLEX EPP 4,0

To be used as a top coat, suitable for new roofs as well as for renovation work.